TCD italia

Regenerative Thermal Oxidizer

The RTO is a regenerative thermal oxidizer plant which turns Volatile Organic Compounds (VOC), hydrocarbons and odors into inactive compounds, CO2 and H2O.

The RTO plant is made of a combustion chamber complete with one or more burners and inlet/outlet sections of energy recovery-dissipation (the number of sections depends on the process data), containing the ceramic heat exchanger.

The oxidation of pollutants starts in the upper layers of the ceramic mass which has been heated up before. The oxidation continues in the combustion chamber to achieve the residence time required. In the outlet section the clean air transfers the heat to ceramic mass.

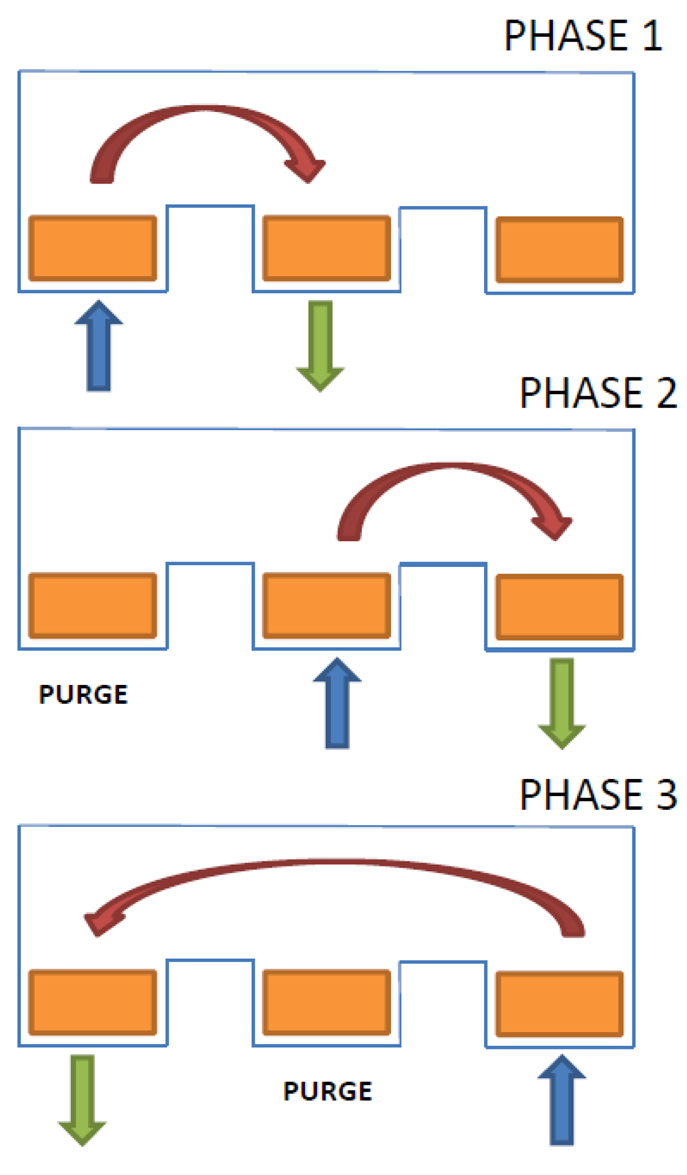

In the next phase, thanks to an exchange made by the valves placed on the inlet and outlet lines, the inlet and outlet section are inverted. In this second cycle the heat stored in the ceramic mass is transferred to the polluted incoming air, saving the oxidation energy given by the gas burning system.

Cycle switches are automatically operated, with no influence on pressure and flow of the exhaust air.

With 3 towers solution, between inlet and outlet phases a purging cycle is acted using ambient air to clean up possible pollutants residuals in the ceramic mass. The purge cycle is done without any interruption or conditioning for the plant function.

The plant is completed with the air conveying system, consisting of a shut-off valve upstream the plant, a fresh air valve for plant start-up and cooling down.

The combustion chamber is suitably insulated to protect the supporting structure from the high oxidation temperatures required for thermal destruction.

The burner is installed laterally to the combustion chamber for easy accessibility. It is complete with a regulation valve train.

The RTO, by using the principle of heat exchange with the ceramic mass contained therein, allow a considerable reduction in fuel consumptions up to their complete elimination, in the case of suitable concentrations of inlet solvents that allow auto-thermal function.

Since the concentration of CH4 is usually limited, this type of plant can be supplied with electric burners (alternatively to biogas, biomethane or network natural gas) that always work at minimum, thus eliminating management consumption.

HEAD OFFICE:

Via Bachelet, 81/83

46047 Porto Mantovano

Mantova – Italy (MN)

WORKSHOP:

Via Pitentino, 5

46037 Governolo di Roncoferraro

Mantova – Italy (MN)

Phone: +39 0376 408149

Email: info@tcd-italia.com

P. IVA: 02453260206