The main use of a burn pit is to dispose of liquid or mixed liquid-vapours relieves as emergency flows or on an intermittent basis when blowing down pipelines or vessels.

The pit is simply a shallow depression or hole in the ground which acts as a reservoir for the waste liquid.

Burn pits may be manufactured with concrete and/or refractory bricks lining. Very large burn pits are frequently left as a natural excavation and surrounded by an earth or rock bund wall.

The liquid in the pit burns and supports its own combustion by radiating heat back from the flame into the liquid at the top of the pool which then vaporizes and heats up further before burning in the flame. The shape of the pool should be selected in order to meet the following constraints:

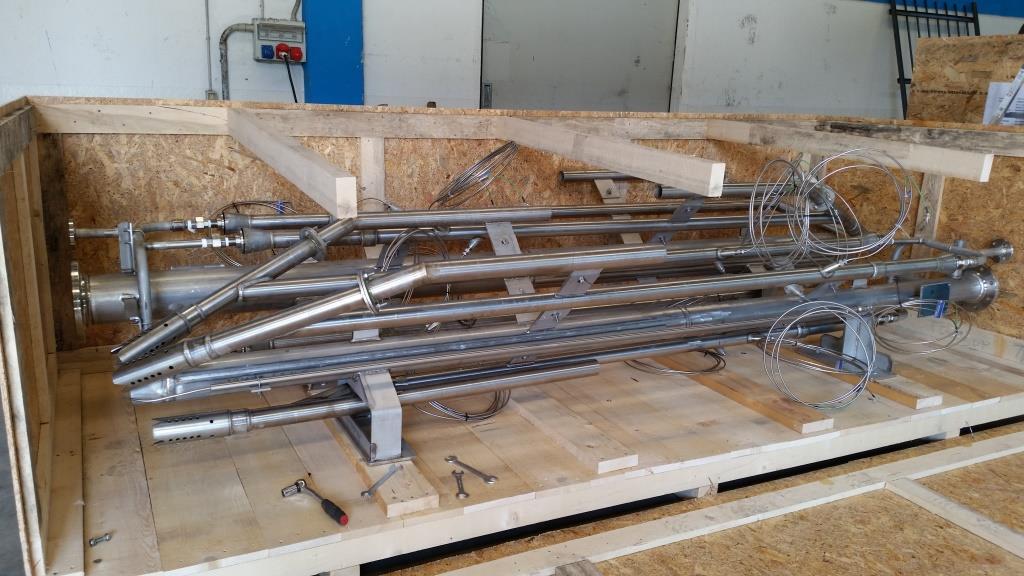

The burn pit burner must be angled downwards to ensure that natural drainage occurs and often liquid relief or residual oil carry-over cannot remain in and it burns inside the pit burner.

The pit burner should be buried in the back-wall of the dike protected by a refractory block in order to minimize heat exposure.

The pit floor should be sloped away from the flare so that residual burning liquid is kept away from the pit burner.

The pit length must exceed the pit burner flame length based on (flashed) vapour.

The pit volume must be sufficient to contain the anticipated liquid loads accumulating over the design hold-up period.

At least two pilots are used for each pit burner head and for large pools extra pilots are spaced around the pit perimeter.

For safety reasons it is important to monitor pilot flames and provide flame failure alarms. Burn pit flaring systems are located away from plant and the minimum recommended spacing is as follows:

150 meters from property line, roadways, process and storage facilities.

60 meters from any source of flammable hydrocarbons.